A lot of good work happening in the shop this week. This thursday the shop hosted its biannual Program Advisory Board meeting. By meeting with industry leaders twice a year, we continue try and improve the methods, practices, and tools used in our shop to give students the best chance to achieve their goals once they leave. Thank you to all our Advisory Board Members for continuing to support the program.

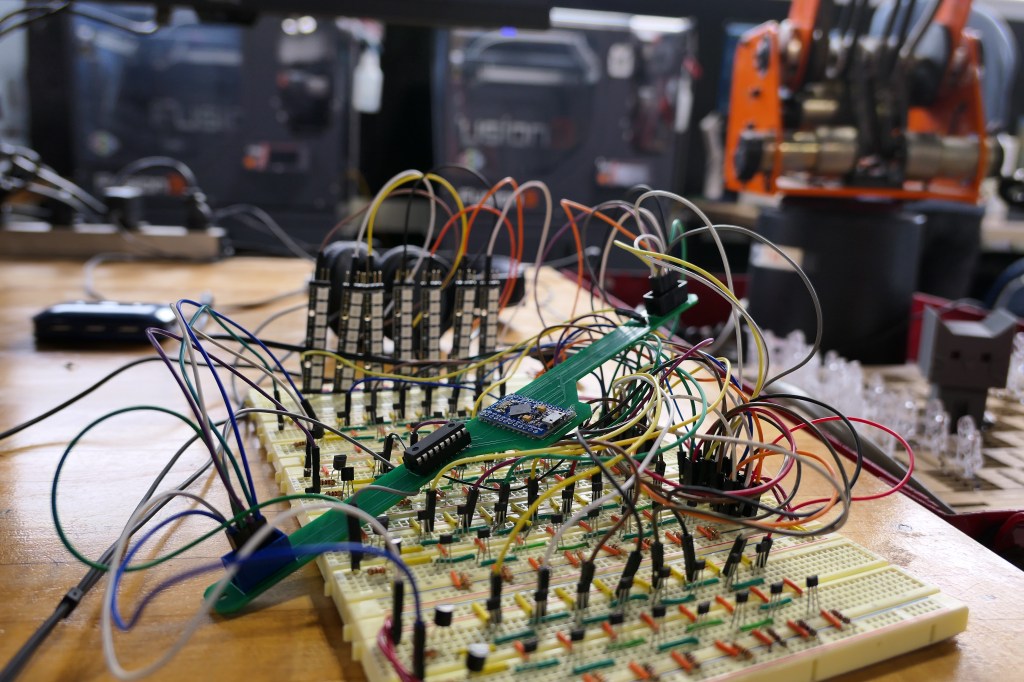

This week Senior Cormac Lynch working through some issues with his PCB. He writes on his blog:

I started the week by helping my classmate Anthony Cartolano work on his PCB. There was a problem with his design that, when transferred to the PCB Mill, would end up creating circles on the board instead of the oval shapes that were in the design in Fusion. No matter what we changed, the problem still continued. I then thought that it might be a problem with his Fusion so I opened the file on my computer and ran the DRC, which ended up working. After we cut the PCB on the mill, I helped him solder a few of the pins to get him started.

Once I was done helping him, I began work on my own project again, switching back to the PCB from the breadboard, but I ran into some problems. First off, the first and second sensor were always activated, meaning that they thought they were being interrupted for some reason. I fixed this by applying more solder to the pins they were plugged into and moving them closer together which got them to work properly. I also soldered four more pins onto the board to plug the display into, and at the end of the day everything was working. However when I resumed work on it the same problem I was having with the sensors before came back, except this time with the third and fourth sensors. I tried the same methods that had worked before, putting more solder on and adjusting the sensors’ positions, but that didn’t work. I’m going to try and fix that issue next week.

See more on his website, click here.

Junior Sanntana Russell continued his work on a robotic arm. He writes on his blog:

wake up sleepy head!

this week I was able to print the bicep after more testing, it works but not in a way I’d like it too.

this week started as most do. I had a hole I needed to measure and fix, this week it was the motor hole. a big problem I’ve had is how friction fit the motor holes are. it wasn’t too hard to fix I just wished I did it earlier. I’ve also tested the peg hole on the ball bearing, not much to say but that it also works.

the biggest part is the bicep and how it changes both a little and alot.

See more on his blog, click here.

The Sophomores were making progress on the coding guides, and have just a few more days of guides left until they begin working on the LED Light Box Project.

Can’t believe Thanksgiving is just around the corner!

You must be logged in to post a comment.