This week Junior Ben Wirz faced some troubles with his float project – but hopefully got things back on track. He wrote on his website:

This week was very disapointing. It started very good, but we were unfortunatly unable to get into the pool due to the webclient being annoying, and to add insult to injury, the whole tube cracked. This means that we will have to create a whole new tube, which will happen today. This really sucks.

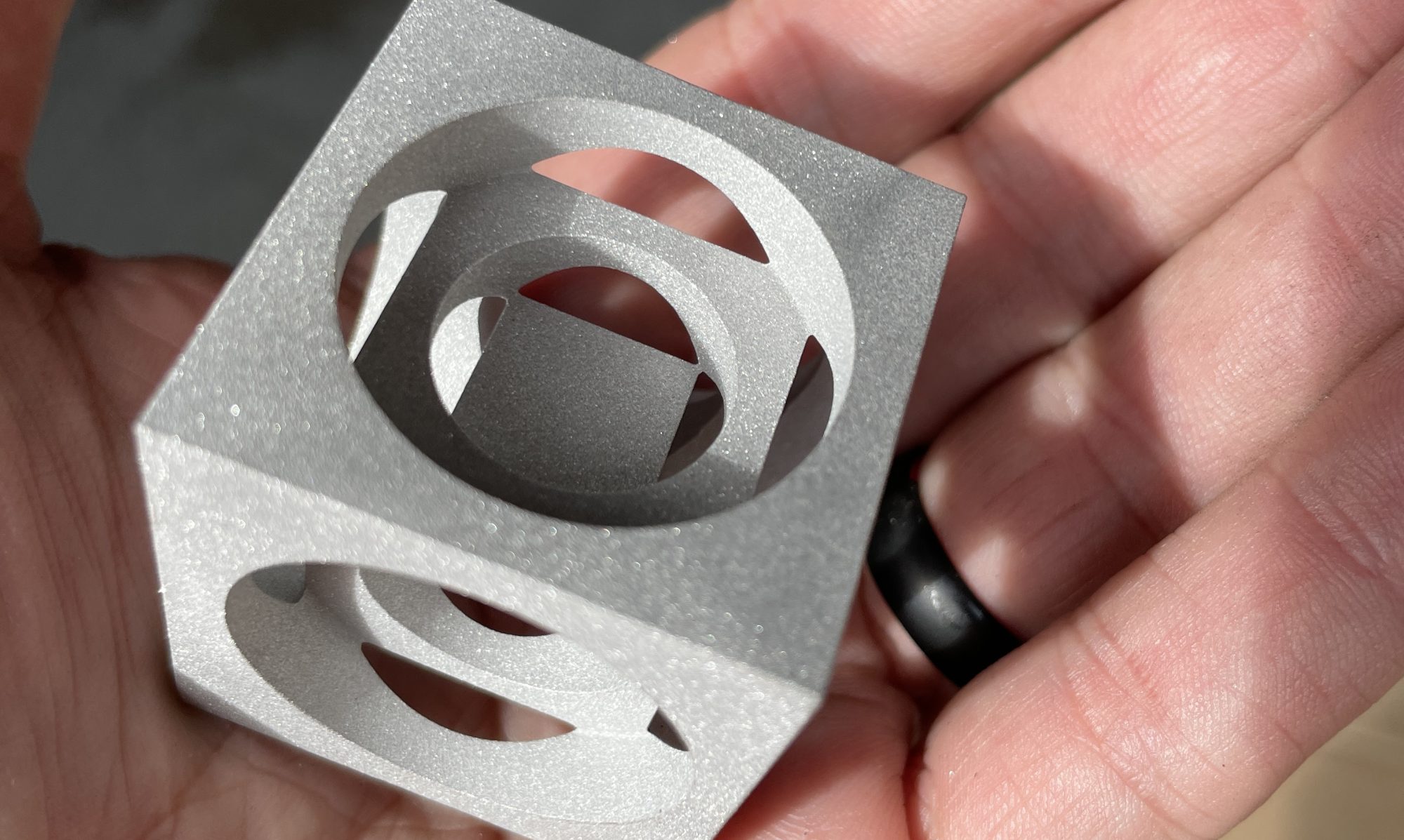

On the topic of the wings, I have selected the NACA 7310 airfoil for the high camber airfoil. I used an online tool by NASA to help gather data for this airfoil, which greatly aided me in the search. Additionally I started to work on the intermediary peice that interfaces with the Wingbody, and the Wing. This is essentially what will allow the wing to be rigidly mounted on the float. I had determined that the pivoting mechanism needs to sit 25mm behind the center of lift of the wing. This will allow the float to be balanced properly in its vertical position.

I have also put that project on the back burner for the time being, due to the catastrophic failure of the tube overnight. I suspect the tube cracked because of the rapid temperature shift, especially because parts of the building lost heat, but it was ultimatly sort of my fault. This is because the magnet holders I designed used set screws against the acrylic creating highly concentrated points of stress. Unfortunatly hindsight is 20/20. I am now redoing this to uses a clamping style holder, that will use a captured nut to hold on.

Read more on his website, linked here.

Senior Cormac Lynch spent time helping others and working on some shop maintenance. He wrote on his website:

This week I started helping out my classmate Anthony Michael Campbell with his jersey project. He had painted it before, but it didn’t turn out very good, so he turned to me for help in his time of need. We started by sanding down the rough edges and spots where the paint clumped up, using both sandpaper and the dremel in the shop. Afterward, we painted the front cover black and waited for it to dry. In the meantime, we also painted the back piece. After those dried, the front cover looked good, but the back didn’t and was very uneven.

We decided to handle that later, and work on painting the jersey’s inside frame instead. When that dried, we sanded it again and repainted it because it wasn’t a smooth paint job. After repainting the inside frame, we thought it was time to finally try and tackle the back again, this time using a roller so we could get a smoother finish.

In between waiting for the paint to dry, I also worked on making a new base for the light project, trying to fix the problem with the light drooping down. I decided that I could make a clamp onto a hole in the table that it’s going in. From what I saw, having a sturdy base reinforced the gooseneck, making it more sturdy and not droop down as much.

See photos and videos from his week on his website, linked here.

The Sophomores continue to make great strides in their work with the Sumobots. Most have perfected motor control and color sensing and each team has the beginnings of a cohesive CAD model. It should be a great Sumobot battle in a few weeks time!

You must be logged in to post a comment.