We’ve arrived in December. This year is moving so fast! Here is the latest happenings in our shop.

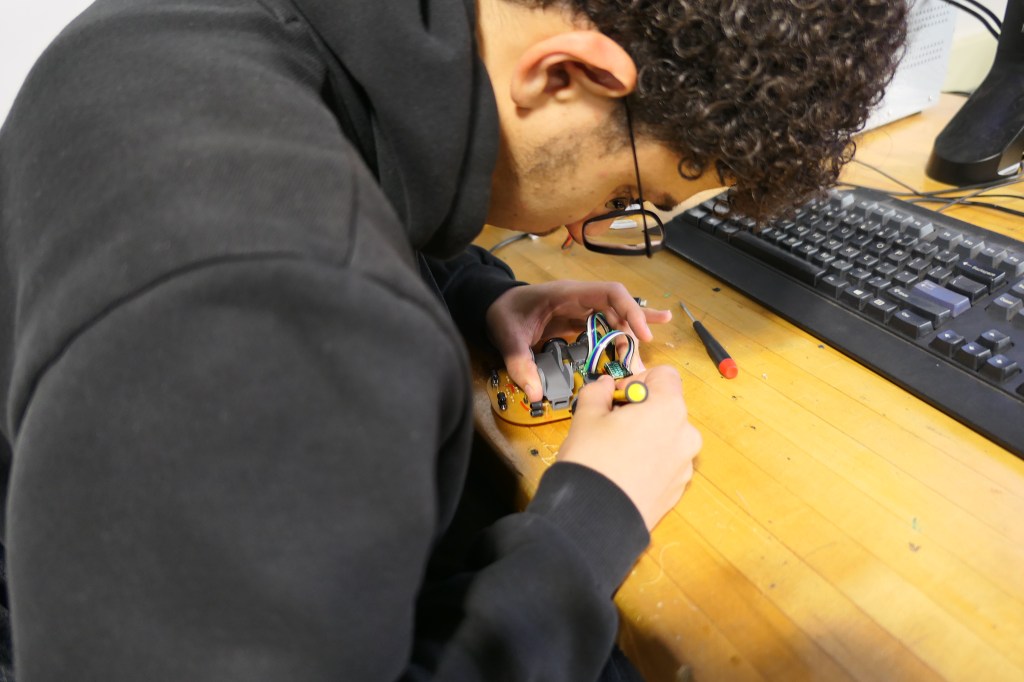

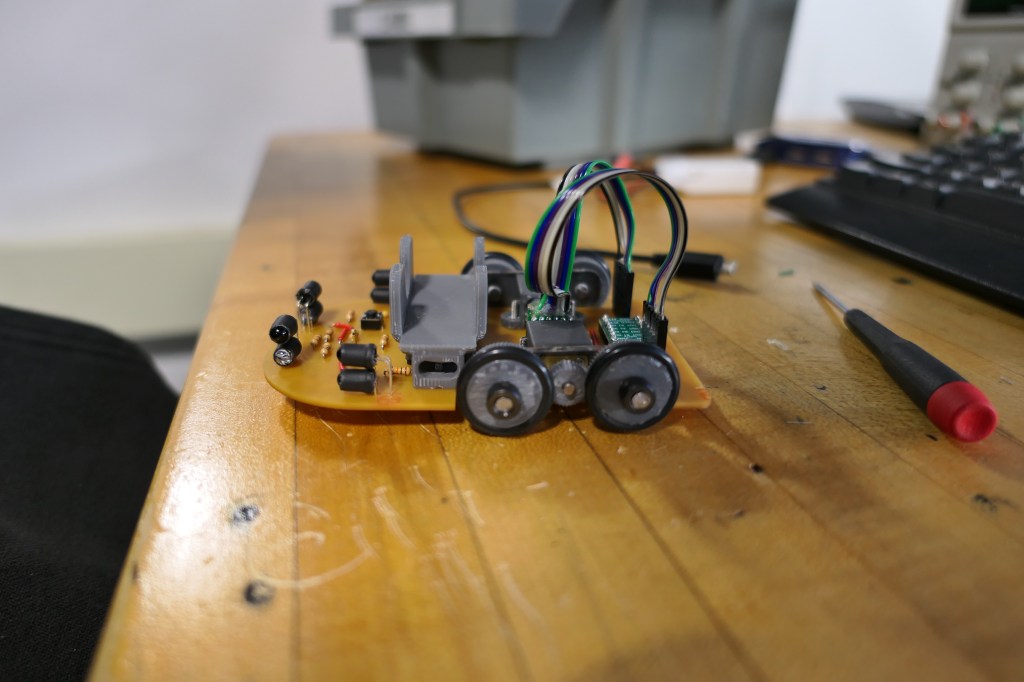

Senior Ben Wirz is working on a project for his science class. He writes on his blog:

This week I started a new project. In my science class we need to do a science project, and Tanzy Azamzy, Joey Campbell and I, have decided to do research on Electromagnetic Fault injection. We specifically want to know how the shape of the Electromagnetic Field generated effects the probability of sucess for each spot on the chip. I am not an expert on this in the slightest, although I do find it pretty cool, however I am pretty good at mechanical engineering for a Highschooler, so my job at the moment is to make a stepper motor controlled XY stage. This is so that we can accuratly position the microcontroller under the emp tip repeatably, and do testing automatically so we can get a large amount of data. Now this wouldn’t be that hard to buy, as precision stages are widely used in automation, however we are highschoolers that don’t have $10,000 to blow on a science fair project. However we can definitly build one.

I would love to build a fully custom stage from scratch, however thats just not feasable. We need this by january at the latest, so building custom linear slides is out of question. What I have done is buy an XY mirometer actuated stage on Ebay. The plan is to simply directly drive the micrometers With little stepper motors and build a little stand and plate for everything to sit on.

In the mean time I have been doing a little bit of design work for the motor coupling, however that has been halted as I can’t continue without the stage and the proper measurements from it. Now I have been working a little on getting a testing board for the stepper motors working which has been a little difficult.

Check out his website at this link to learn more and see photos.

Junior Lincoln Bell continues his work on his Gyroscopic Train.

I spent this week machining aluminum flywheels to use on my gyroscopes, because the Acrylic ones I’ve been using aren’t heavy enough to overcome the weight of the balancing rig, so in order to do any real balance testing, I need to make heavier flywheels so the rig can stay upright without support.

My original plan was to design flywheels with a groove around the middle, but the lathe in the shop wasn’t able to do it, so instead I just made two flat discs.

Learn more about his project at his website, linked here.

The Sophomores began their LED Lightbox Project. This project will teach them how to create a custom circuit board, manufacture an electronics enclosure, design an acrylic sheet etched to reflect LED light, among many other skills and lessons. Can’t wait to see their final products!

You must be logged in to post a comment.