Only 4 days of school this week due to the Rosh Hashanah holiday, but our students were still cranking along in the shop. Here is a brief summary of some of the work happening.

Junior Scott Campbell has been updating his website in advance of his upcoming Coop opportunity. Next week Scott will be working half the day in a real work environment. While we will miss having Scott in the shop each day, we are excited for this new challenge he is undertaking. Here is his most recent blog post:

When I tried to build my website on FreeBSD I noticed that there were some problems with my template. I realized that it was because many of the features that were being used in my template Hugo Blog Awesome were deprecated. Thankfully it is still being updated, and I was just using an old version.

I had never updated it so I head to lean a little bit more about git. I use git submodules for my website which are optional, but I like that it comes bundled in with the git repository. I found that I only needed to run

git submodule update --recursive --remote.Tanzerul finally got the axle kit he ordered on Amazon. It came in many parts and he needed some help assembling it. The kit came with wheels, a chain, pillow block bearings, a break disk and break calipers.

This axle is not exactly quality, but it is probably good enough to do the job given that we will not be driving it at go-cart speeds.

There were no instructions with the kit but it was fairly intuitive. The only real missing piece was that it did not say how much to torque the bolts down by, so hopefully our guess was good enough.

The other issue with the axle is that it is a little bit shorter than the shopping cart is wide so it will take some engineering to get it to fit on the cart. Currently the plan is to weld some tube stock to extend the back and connect the axle behind the shopping cart.

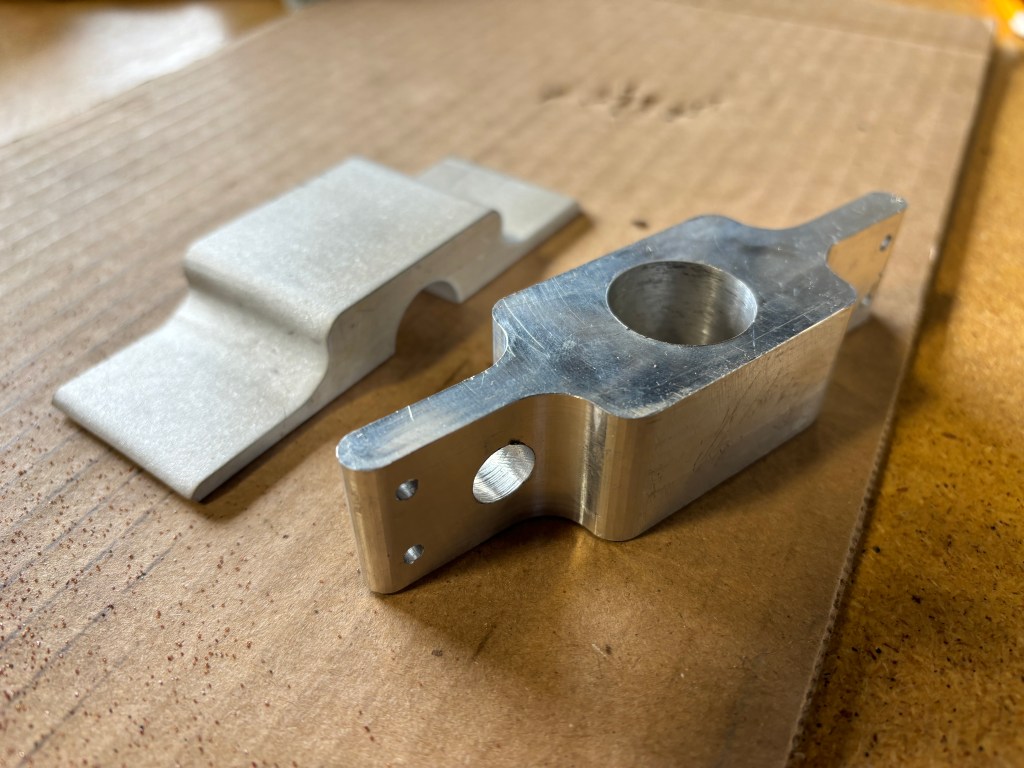

Ben has been working on getting the shopping cart mechanically ready to be have autonomous steering. He needed some help getting a bearing into the housing. It was an interference fit meaning that it needs to be pushed very aggressively into place because the hole is intentionally a little bit smaller than what needs to be placed into it.

It was in a location where we could not hammer the bearing into place because of an unfortunately placed support.

We looked around for a car jack that we could place against the support to push the bearing into place, but we could not find a jack.

Check out Scott’s website for more information, linked here.

Junior Bella Hallahan has been working on updating her LED Light Box. She writes about the project on her blog:

This week, I spent most of my time trying to get my PCB to work. It took a while to figure out what was wrong with it because it would be working one minute and not working the next. The temperature sensor was being really finicky and weird. It turned out that the issue was the wires I had connecting the temperature sensor to the board. They were not crimped well enough, so I re-crimped the wires and the PCB works now.

This week, I also made one of my acrylic pieces in Inkscape, tested it in cardboard, and finally lazer cut it in acrylic.

See photos and more at her website, linked here.

You must be logged in to post a comment.