Well, this will be the last post of the year. We have been so grateful for all the hardwork students have put into the shop this year. It has been our pleasure to help them achieve their engineering goals and build some incredible objects. Here are just a few shop highlights from the year.

First, Milo Austin has nearly completed his custom built electric guitar. His base guitar was first designed in Fusion 360. Next we used the Tormach milling machines to create the bridge. The routers was used next to make the body of the guitar, while the water jet was used to produce the pick guard. It’s an incredible project, and its been great to see Milo so excited to produce a product he really wants.

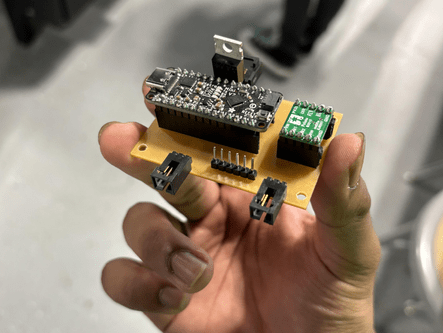

Senior Roman Rice has worked tirelessly to get the golf cart working. His hard work has paid off, as we now have control of the the golf cart through his custom circuitry. He has been able to recreate a control system for the cart via a custom PCB. The students have been driving it around making sure it works properly, and it’s a nice addition to help take our trash up to the dumpster. We are looking forward to continuing the work next year on making this golf cart autonomous.

Also, senior Shubh Patel finished the 2D plotter, an automatic drawing machine. He has created a web interface that allows one to submit an image, which is then processed by software and sent to the plotter. The plotter will then draw the image and move the paper forward to a clean area ready for another image. It’s a brilliant piece of custom engineering, and we hope to print a lot of great images over the years.

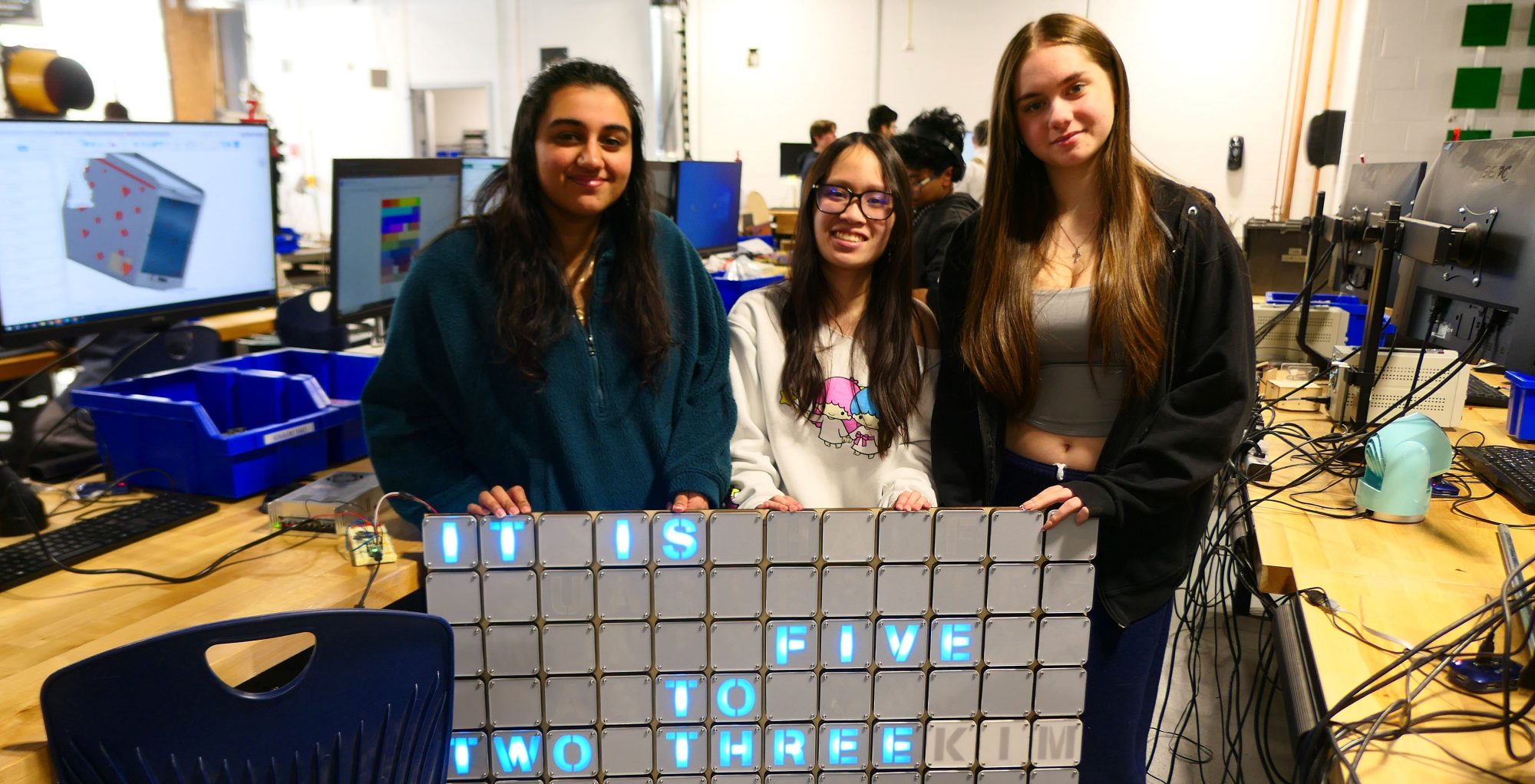

Our sophomores made some of the best Sumobots and LED Lightboxes we’ve seen to date. They learned the basics of making custom circuit boards and turning CAD models into actual objects via our laser cutters and 3D printers. They’ve taken some big steps towards being able to make their own DIY projects in our shop next year.

The Freshmen closed out the year in the machine shop using our water jet. Students designed custom name plaques in Fusion 360 using the Sheet Metal tools function. They were then able to export these files to the water jet, which cut them as flat pieces of aluminum. After that, they used our pan brake to bend metal to the correct shape. We hope to make many more projects with them in the machine shop next year!

Lastly, our Robotics team is once again heading to the World Championships. This year they won the New England Regional Championship for the 3rd year in a row. They will be heading to Tennessee on Sunday for the competition. We wish them the best of luck and hope they bring back a 1st place prize!

You must be logged in to post a comment.