This week we transition from January to February and are closer to the first completed project for our sophomore students. The LED lightboxes have a deadline for completion by the February break, just a few weeks away. Looking forward to seeing the completed projects.

This week Junior Aaron BenDaniel took a break from the ROV to work in the machine shop. He writes about the project on his blog:

I spent most of this week working on my Machinist’s Jack project. I spent the first two days attempting to turn the head of the jack, and I almost completed it. However, the threads I made had too high a diameter because I made the assumption that 1/2-13 screws are actually 1/2in wide. This is not the case. I attempted to save what I had made but ultimately had to scrap it. It did serve as a refresher on how to use a lathe, though, as I had very little previous experience using them before.

Wednesday after school I and a number of other team members wrapped our tether. Although I’m still not sure how we’re going to add flotation to it, at the moment I think the tether is in a very good place right now. I also added strain relief to the tether on the ROV’s side. I intend to use the same system on the surface, but need to find one more part before I can finish that.

Wednesday and Thursday I made the base of my Machinist’s Jack. It’s not quite done, with just a little but of facing left to remove the excess material on one side, but other than that this part is done.

See photos on his website, linked here.

Senior Cormac Lynch continued his work troubleshooting a PCB. He writes on his website:

I started off this week by reprinting the bottom of my PCB holder. Initially I had the screw holes on the opposite sides that they were supposed to be on so the two parts of the holder wouldn’t screw into each other. After reprinting that and ensuring that the screw holes were in the right place, I tried to put them together, but we didn’t have long enough m2.5 bolts to go through both sides of the holder, so they couldn’t stay together. I plan on getting longer bolts in order to hold them together.

Unfortunately the next day I accidently dropped my PCB, messing up several of the pins so I spent some time fixing those. I then had to test them with a multimeter afterward to make sure that they still worked.

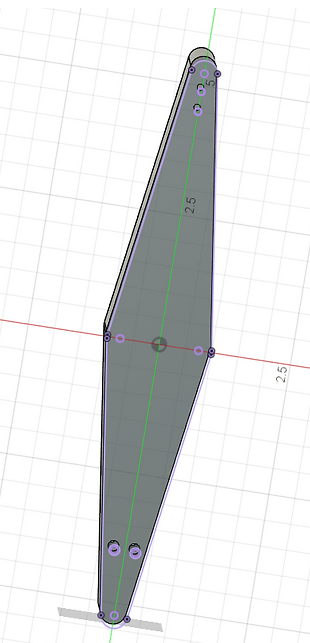

Finally, I also worked on designing a mount to hold a light for workstations in the shop that could be dark, making it harder to get work done. In order to hold the light up I designed a wall mount(pictured below), which I’m going to cut using the water jet, then bend in the middle.

See more at his website, linked here.

You must be logged in to post a comment.